The right packaging is crucial for preserving product quality and extending shelf life—and that includes the closure lining material. Pressure seal lining, foil seal lining, and foam lining materials are all popular choices, and offer distinct advantages and drawbacks that must be carefully considered based on your specific needs.

In this post, we’ll review the pros, cons, sustainability, and cost of the three main types of lining materials, to help you decide which will work best. If you still have questions after reading this article or aren’t sure which to choose, our team would be happy to help! Contact us anytime.

Pressure Seal Lining

This lining material is widely used due to its effective sealing properties and comparative affordability. Advantages include:

- Seal effectiveness: Pressure seal lining provides a tight seal, preventing leaks, contamination, and moisture ingress. It ensures product integrity and extends shelf life.

- Barrier protection: This lining adds an extra layer of protection without requiring additional equipment like an Induction Heat Sealer.

Disadvantages:

- Sustainability: Pressure seal lining often involves non-recyclable materials like plastics, which can contribute to environmental concerns. However, some manufacturers are starting to offer eco-friendly alternatives made from recycled materials, reducing the environmental impact.

- Limited tamper evidence: The FDA has not explicitly approved pressure seal liners as a tamper evidence container, so they commonly require additional shrink bands or induction foil seals for true tamper evidence.

- Cost-efficiency: Although pressure seal liners were once considered cost-effective compared to other sealing options, pressure seal prices have increased recently due to limited sourcing and legislative initiatives for more eco-friendly alternatives.

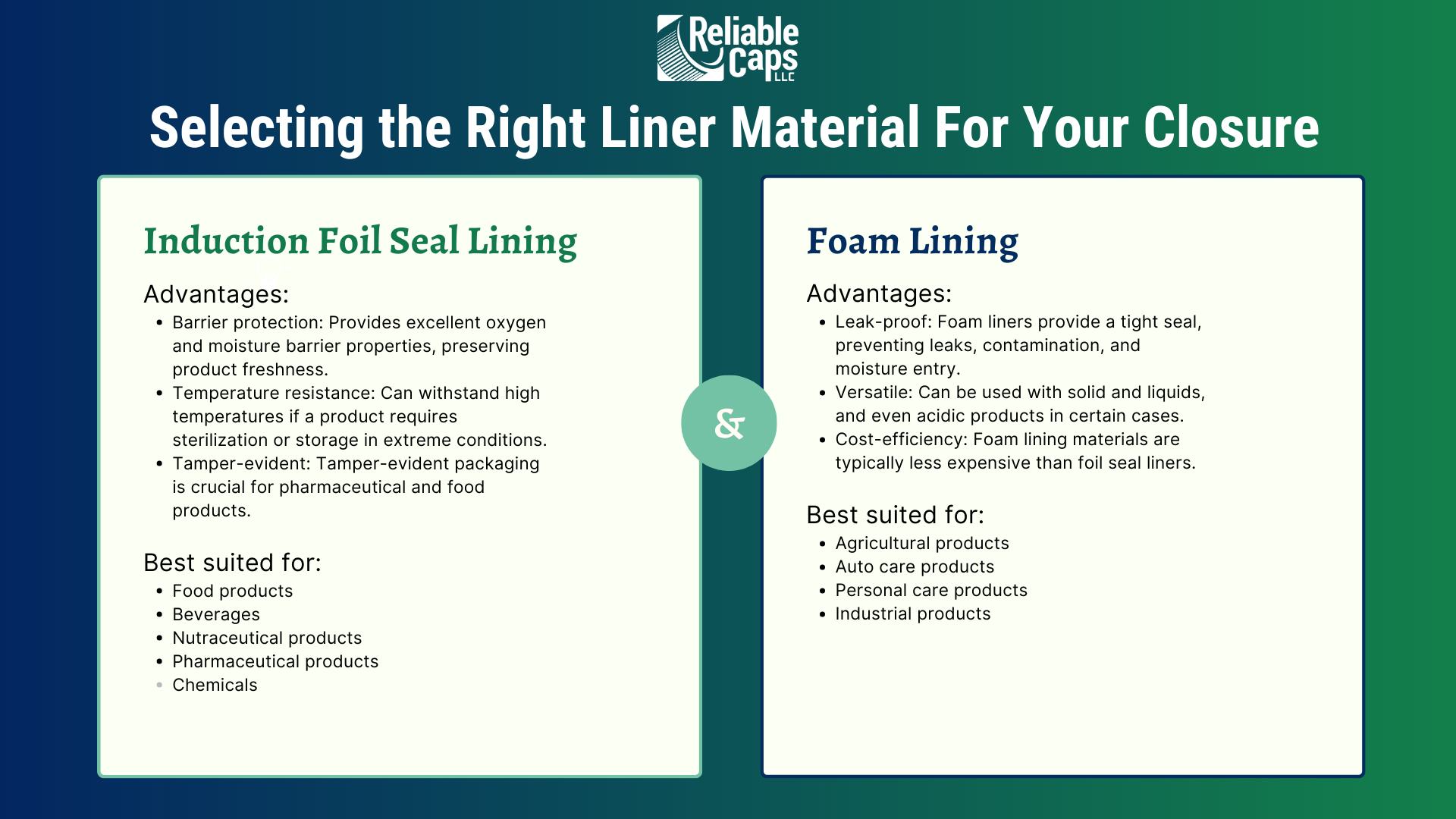

Induction Foil Seal Lining

This lining material is popular due to its strong barrier properties and ability to withstand extreme conditions.

Advantages:

- Barrier protection: Foil seal lining material provides excellent oxygen and moisture barrier properties, preserving product freshness and extending shelf life.

- Temperature resistance: Foil liners can withstand high temperatures, making them suitable for products that require sterilization or storage in extreme conditions.

- Sustainability: Foil seal lining materials can be recycled, promoting environmental sustainability.

Disadvantages:

- Cost: Foil seal lining materials tend to be more expensive than other options due to the cost of raw materials and manufacturing processes.

- Efficiency: Foil seal liners can be challenging to apply uniformly, requiring specialized equipment and careful handling.

Foam Lining

Foam lining material is valued for its sealing adaptability and versatility with an array of packaging applications. Advantages:

- Effectiveness: Foam lining material can provide a tight seal, preventing leaks, contamination, and moisture ingress, even when bottle landings are varied or slightly deviated.

- Versatility: Foam liners can be used with solid and liquid products, and in certain cases, acidic products.

- Cost-efficiency: Foam lining materials are generally less expensive compared to pressure seal lining materials, making them a cost-effective option for businesses.

Disadvantages:

- Environmental impact: Traditional foam materials are not biodegradable and can contribute to landfill waste. However, manufacturers are now developing eco-friendly alternatives using biodegradable or recyclable foam materials.

- Limited reusability: Foam lining materials can deteriorate over time, reducing their reusability and potentially requiring frequent replacements.

As we’ve seen, each of the three lining materials—pressure seal, foil seal, and foam—comes with advantages and disadvantages. Ultimately, the best choice depends on the specific requirements of your product, cost considerations, sustainability goals, and the desired level of protection. Once you’ve weighed the pros and cons, get in touch with our team with any further questions or to place an order!