Choosing the right induction liner is one of the most important parts of assembling a safe and reliable package. Used across a wide variety of industries, induction liners prevent leakages by ensuring your container is airtight. Not only do they add an extra layer of protection, they also provide customization that can differentiate your product from others on the market. Here’s an overview of induction liners.

What is an Induction Liner?

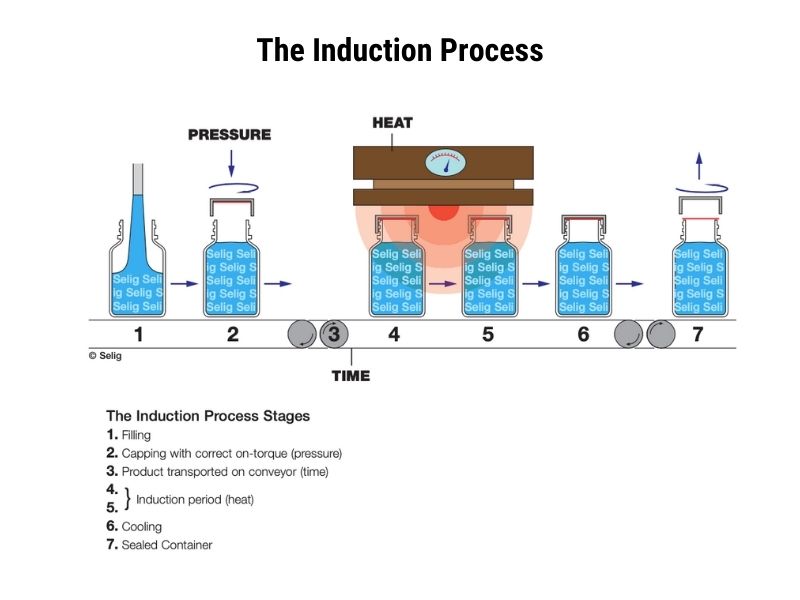

If you are looking for an extra layer of protection beyond just an unlined closure, induction liners are a great solution that can easily be added to our closures. Induction liners, also known as heat seal liners, are air-tight seals on the top of plastic or glass containers that are bonded using electromagnetic induction heat after your bottle has been filled and capped. Pressure and heat are applied to the seal for a predetermined period of time, creating a seal that protects product freshness, prevents tampering, minimizes the chance of potential leaks, and can even add an additional level of customization that makes your product stand out.

When Should You Use an Induction Liner?

You may choose to include an induction liner for a variety of reasons. If your products require an air-tight seal to stay fresh (like spices, for example), induction liners are a great option for you. Induction liners can also fulfill requirements for products that need a tamper-evident seal. Additionally, induction liners can be used for products that undergo extensive shipping processes, as they provide another layer of protection against potential leaks. This is especially true in e-commerce scenarios where it is unlikely a bottle will remain upright throughout its ultimate journey to the consumer. Even if your product doesn’t fit into any of these categories, induction liners are customizable and can help set your product apart from the competition.

How to Select the Right Induction Liner

The first step to selecting an induction liner is determining what material the bottle is made from. There are different induction liners for HDPE, PET, glass, etc. There are even “universal” induction liners that can be used for a wide range of bottle material types; however, we typically recommend using an induction liner that is specific for the bottle to which it will be adhered.

The first step to selecting an induction liner is determining what material the bottle is made from. There are different induction liners for HDPE, PET, glass, etc. There are even “universal” induction liners that can be used for a wide range of bottle material types; however, we typically recommend using an induction liner that is specific for the bottle to which it will be adhered.

The right induction liner for your container will vary based on the type of product you have and what your individual needs are. Multiple layer options allow you to ensure that any contents will be protected, from food to chemicals and beyond. The composition of your induction liner will mostly depend on your product’s contents, and whether or not a reseal is required after opening.

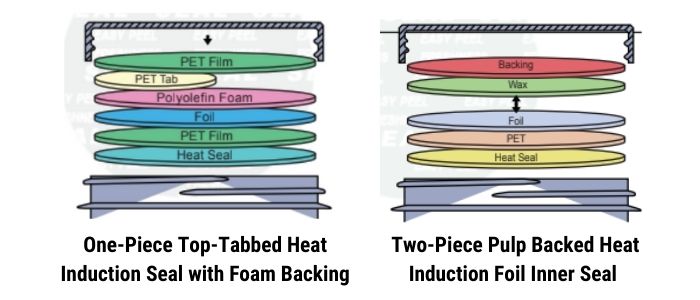

For containers where a reseal is not necessary, standalone one-piece liners with layers of PET (polyester), foam, aluminum, and sealant are used. These include the commonly seen lift-and-peel liners that have a tab for easy seal removal.

When a reseal is required, you will need a two-piece lining solution. This can be accomplished by first lining the closure with something like a pulp or foam liner and then lining with a 1 piece heat seal liner. A more cost effective two-piece lining solution utilizes a pulp or foam backed, wax-bonded liners that allow containers to be resealed after opening. The composition of the layers that make up the two-piece liners will depend on the type of liner as well as the contents of your product.

What is a Leaker and How Do We Prevent Them?

One of the purposes of induction liners is to prevent leakers, which occur when the induction liner is unable to seal completely to the top of the packaging, and the contents of the container are able to escape. If there are issues with the amount of pressure, heat, or time applied to an induction liner, leaks can sometimes occur.

Regarding the pressure component, this has to do with the application torque at which the closure is applied to the bottle. Problems with torque arise with inconsistent torque, over torquing and under torquing.

A common cause of leakers that we hear about are induction liners getting overheated in the heat induction process. Overheated induction liners can melt and burn pinholes through the liner. This happens if the heat induction level is set too high and/or the cap spends too much time under the heat induction head.

A large number of the leakers we hear about are caused by problems with the bottles. Bottles with land areas (the top area that comes in contact with the induction liner) that are not completely flat can prevent seals from bonding properly.

Why Choose Reliable Caps For Your Induction Liners and Caps?

No matter what kind of induction liner you need, we can work with you to find the right closure and liner solution. Whether you are a brand new company looking for a small quantity of caps and seals, or a national company needing large, customized orders, we offer personalized customer service and regular follow-ups to ensure you are getting exactly what you need. We work hard to provide you with the shortest lead time possible, without sacrificing quality. Contact us to discuss your cap needs.